Continuous Level Measurement

VEGA develops and manufactures sensors for the measurement of level, point level and pressure along with software for integration in to process control systems.

Vega’s measurement Continuous Level Measurement instruments supplier in Pune Indiatechnology sets new standard in reliability, accuracy and economy for all the media & process conditions. Vega level products are widely used in Chemical, Mining & Metal processing, Energy, Oil & Gas, Paper, Food & Pharma and Water / Waste Water Industry.

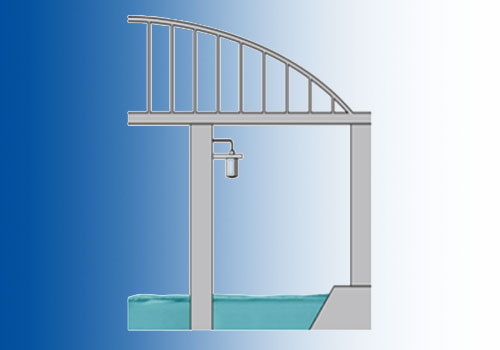

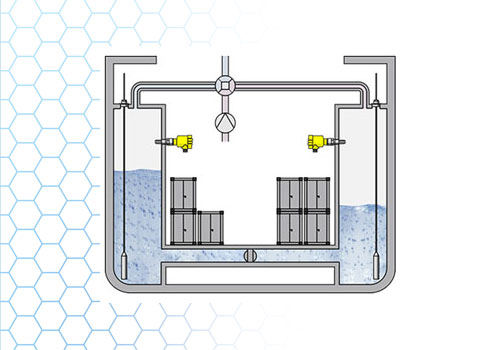

In continuous level measurement, the level of a medium in a tank or silo is detected with the help of different measuring methods and converted in the an electronic signal. The level signal is either directly displayed on site or communicated to a process control or management system. Typical applications for continuous level measurement are process tanks, storage tanks or silos in the process industry. The measured media are liquids, pastes, powders and bulk solids.

Vega manufactures Radar, Guided Wave Radar, Ultrasonic, Capacitance, Hydrostatic and Radiation based level measurement products and solutions.

Radar Level Measurement

This is the most accurate and reliable level measurement method suitable for almost all the process conditions. This is non-contact level measurement where measurement is not affected by process pressure, temperature, dust, condensation, fumes, etc. Liquids and Solids are commonly measured with this technique.

Vega has wide range of radar level transmitters suitable from simple application to extreme challenging applications. Pioneer in 80 GHz Radar technology.

Because of 80 GHz frequency, the beam angle is extremely small which allows level measurement in small tanks as well as narrow vessels with stirrer or heating spirals. It has got very high signal to noise ratio.

Can be used for level measurement up to 30 m in liquids and up to 120 m in solids. Variety of process connections and wetted part materials allows it to use in -40 to +200 deg C temperatures. The output signal 4-20 mA HART, Profibus or Foundation Fieldbus is available as required by customer.

Radar Level Transmitter for simple applications

Level Switches

The point level sensors are used in homogeneous liquids and bulk solids in the tanks and pipelines. They serve as overfill protection and dry run protection. They can also be used for foam detection and liquid media differentiation, e.g. oil-water detection. They are also suitable foe safety-related applications up to SIL2. Special materials & coated versions also allow their use in aggressive media. For solid applications, the point level sensors can be used for empty detector in silos and bunkers coating bulk solids. Typical applications include material such as plastic granules, pellets, cement, sand, flour and non-adhesive media.

Capacitance, Vibration (fork / rod), Conductive and Microwave types point level sensors are manufactured by Vega. Microwave type level switch is the only non-contact point level measurement while all other types are contact type point level measurement. The switching command starts or stops filling equipment such as conveyors or pumps.

Cost-effective limit switches are available with universal connections for hygiene adaptors ensures reduced installation effort and leaner stock keeping and perfectly meets the requirements for hygienic processes in food, beverages and pharmaceutical industries.

Conductive & Vibration Type Level Switches for Liquid and Solid applications

Pressure Measurement with Ceramic Diaphragm

The robust, all-round pressure sensor with ceramic measuring cell. The ceramic measuring cell is resistant to temperature shocks. The pressure sensor is available with innovative flush mounted ceramic measuring cell that VEGA manufacturers. The measuring ranges of pressure transmitters start at a few mbar and extend to extreme pressures up to 1,000 bar

The pressure transmitter can be used universally for the measurement of gases, vapours and liquids. Substances such as sand can be handled easily thanks to the abrasion-resistant ceramic measuring cell.

Convenient wireless setup and diagnostics with smartphone. Easy integration into control systems through IO-Link communication.

Stainless steel housing suitable for food and pharmaceutical industry.