Within the intricacies of fluid dynamics, is a device capable of measuring fluid flow without causing excessive pressure loss. Finding its applications, varied industrial domains; venturi tubes are a crucial instrument in maintaining precision and accuracy. Join us as we dive into the world of venturi tubes and explore their important applications.

What are Venturi Tubes?

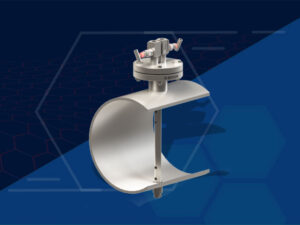

A cylindrical cross section with narrowed centre portion (flanked by wider ends) accelerating the flow velocity is a venturi tube. Giovanni Battista Venturi designed this marvel based on the Bernoulli’s equation. The concept states that, as the velocity of fluid increases, it experiences a pressure drop. Widely used concept is employed in multiple flow measuring devices.

How a Venturi tube works?

Working of a venturi tube is simple yet quite effective. When the fluid enters the narrow section of the tube, its speed increases, correspondingly raising its velocity. As the velocity of fluid increases, its pressures decrease’s. Once this fluid is exposed to the wider entrance of the tube, its velocity is reduced quickly which builds up the pressure. This pressure developed on the wider section can also be termed as recovery pressure. By measuring the difference in pressures on both the sections of tube, we can calculate the flow rate. Thus, a venturi tube can also be employed for precise flow control and measurement according to the type of fluid flow

Applications of a Venturi tube

- Oil and Gas industry: In the oil and gas sector, Venturi tubes are employed to measure the flow of hydrocarbons and other fluids, ensuring accurate allocation of resources

- Chemical Manufacturing: Accurate flow measurement is critical in chemical manufacturing, and Venturi tubes help maintain precise control over chemical processes.

- Aerospace and Aviation: Venturi tubes are used in aircraft and rocket propulsion systems to measure air or gas flow and control fuel injection rates.

- Automotive Industry: In automotive applications, Venturi tubes are used for measuring air intake in engines, ensuring optimal combustion and fuel efficiency.

- Waste treatment processes: They help in precise dosing of chemicals for pH control and coagulation.

Advantages of Venturi tubes

- High accuracy: Venturi tubes provide highly accurate flow measurement readings, making them an ace choice where precision is the key factor.

- Low pressure losses: Since venturi tubes have low pressure losses compared to other devices, the energy losses while flow measurement are highly reduced.

- Durability: Efficient design, use of robust materials and adaptability makes venturi tubes ideal selections for prolong applications.