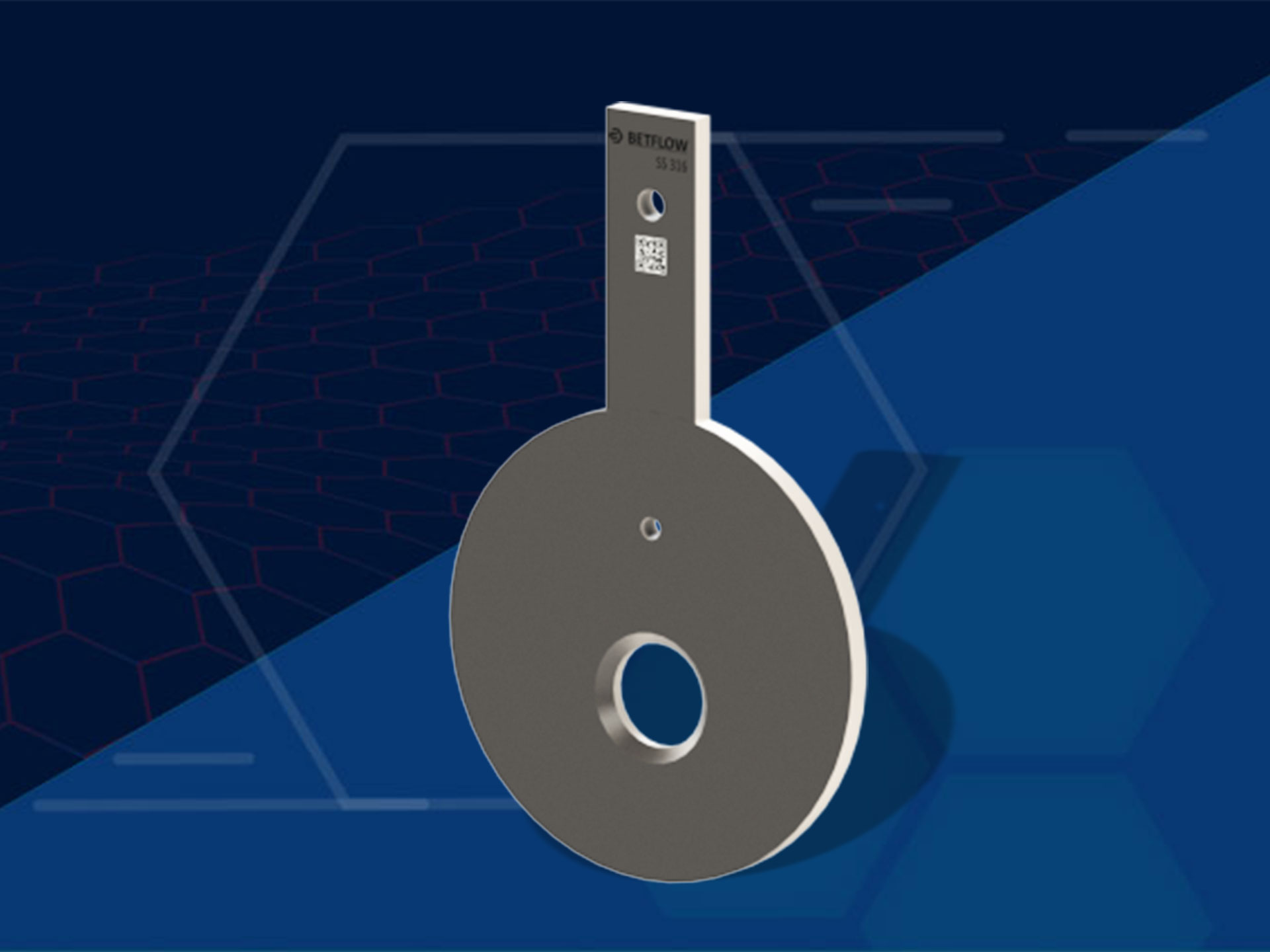

Unlike the concentric counterpart, this orifice is positioned to the lower side of the plate. In the world of flow measurement, precision and accuracy are paramount. Eccentric orifice plates prove to be a reliable and accurate instrument in flow measurement.

The off-center orifice design allows the plate to better handle the flow containing solids, slurries etc. One of the key advantages of eccentric orifice plates include improved turn down ratios.

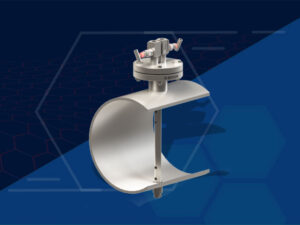

Compared to other types, eccentric orifice plates create a gradual pressure drop when subjected to flow, which reduces the risk of cavitation or formation of vapor bubbles. Eccentric orifice plates give accurate readings even in non-standard flow profiles, making them highly adaptive.

Applications of Eccentric Orifice Plates:

1. Petrochemical plants: Gas liquid separation is the key consideration in petrochemical plants. Eccentric orifice plates are often useful here as they allow gas bubbles through the plate without blocking the measurement orifice, hence providing highly accurate readings.

2. Mining: The offset design reduces the risk of solid particles settling around the orifice hole, thereby preventing clogging and giving precise readings.

3. Water treatment plants: Ability to accommodate varying flow conditions makes them well suited for flow measurements in water treatment plants.

4. Oil and Gas production: In the oil and gas industry, eccentric orifice plates are used in custody transfer applications to measure the flow of hydrocarbons.

These are some of the applications of the Eccentric Orifice plate. Let us know if there are any, which we’ve missed out.